Just picked the car up. Ken worked hard on this one! Haha. Nothing is simple when it comes to old cars and their upkeep and repair. Some parts may be 40 years old and you NEVER know what you have until you get into the guts of the job.

The plan was to strip the block down in the car. Pull the pistons out and replace the rings then put it all back together. The things to worry about were the block itself. Whats the condition of the cylinder walls? Luckily the cylinder walls were in good shape. The rod bearings were tired so they needed to be replaced. The surprise was the pistons. The ring landings where the rings fit in were WAY out of spec. The other surprise was the actual pistons in the car were low compression pistons. So I set out on a mission to find a set of 89.47mm high compression pistons that will work in a late model e12 M10 head. There are 3 heads used on the M10 engine. So the pistons have to be matched for the head. They also have to be the correct diameter. 89mm is the stock piston diameter. As it wears, you have it bored out slightly to get a perfect bore and take out just a little material and you replace the pistons with a slightly larger diameter piston. So my block has been bored slightly in its 40 or so year life. The problem with that is as you bore it more and more the cylinder walls get thinner and thinner and this compromises the durability of the engine block. The advantages of boring the cylinders is you increase the engine displacement thus making it more powerful. If I was doing a true rebuild I would have gone up to the next size piston, 90mm. I will also go with a shorter piston and longer rods to increase the stroke, or make it a "stroker".

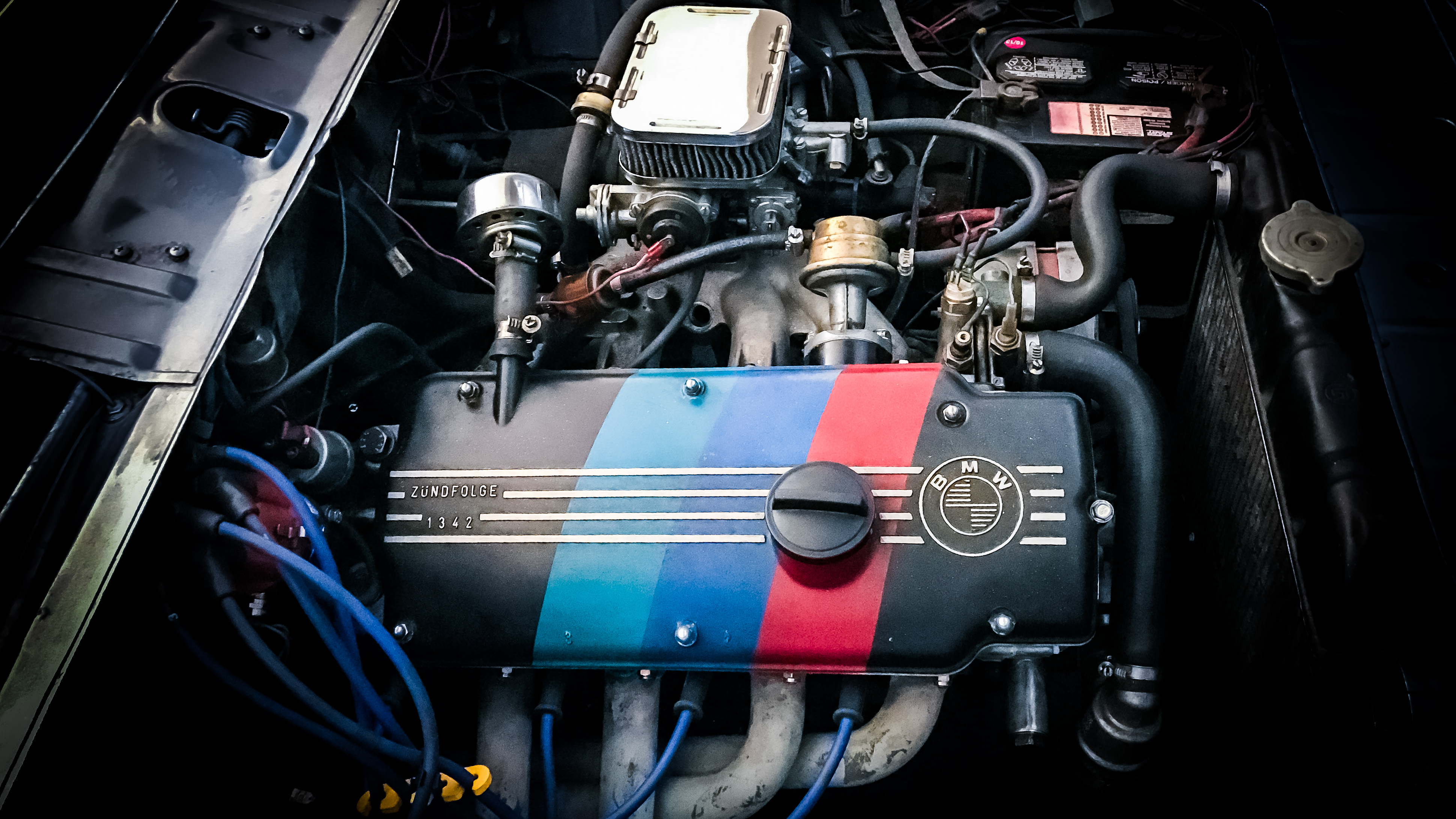

So finding a 89.47mm high compression piston wasn't exactly an easy task, but I found a set in Kansas City and had them shipped to Ken. They were used so we had to make sure they didn't have the same issues as my pistons. The pistons were within spec so they went into the motor. The oil pump was refreshed. The top end was rebuilt about 2 years ago with new valves, valve stems, cam, rockers and valve springs, so there was nothing needed except a valve adjustment to the top end. Once the engine was complete then Ken gave it a pretty good tune. It was his first time with the 123/Tune distributor and he liked it! He was not only able to give me a pretty good curve but also dialed in vacuum very nicely as well. Sweet! He also replaced the Guibo as well as the bushings in the shift platform. I drove the car and it's got a nice smooth power delivery, the shifter feels like I'm driving a different, much more modern car. In a very good way. Very direct shifting. It was very vague before, now it's very precise. It's got a smooth idle and that flat spot in the midrange is gone. He also replaced my spark plug wires, a soft motor mount, fixed an exhaust stud oil leak, replaced an exhaust gasket, checked the float level and rejetted the Weber 38/38 carburetor.

After just a few hours of driving it, I am very pleased with the outcome. Smooth and pepper are the words that come to mind. I covered the tailpipe with my hand for maybe 20 seconds and there was ZERO oil spray or anything like that coming out of the tailpipe. That's the second of the 3 major things that needed to be done to the car. The last major work to be done is the 5 speed conversion. Before that happens though, I need to reseal the rear window, get a front end alignment, finish the BBS wheel refurb, install the longer rear studs, clean up the engine bay wiring, get the headliner fixed, install the chrome belt line trim, install the air dam,finish the coilovers and maybe rechrome the bumpers. Phew! That will keep me busy!