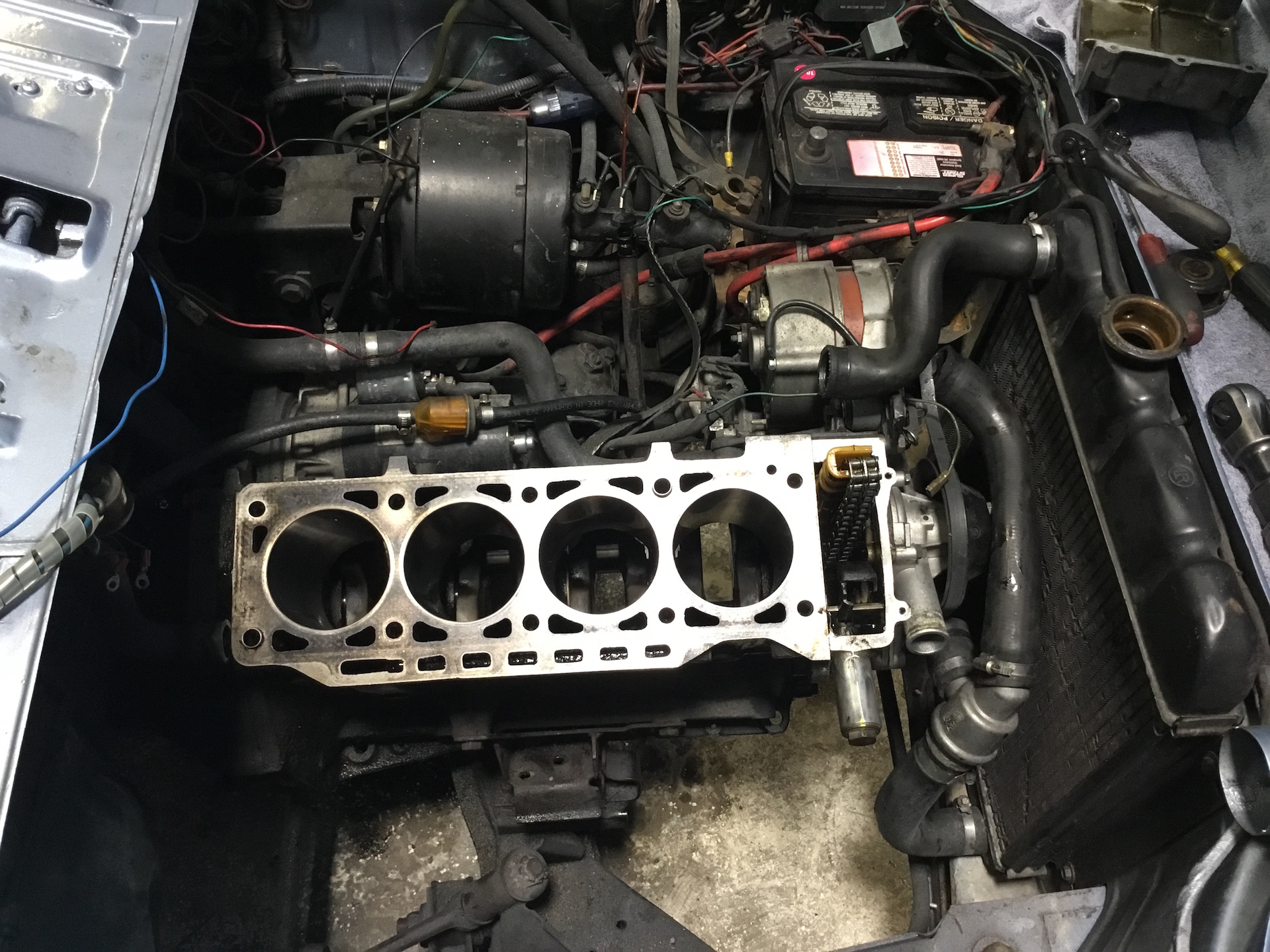

Bottom end refresh is underway and its mostly going smooth. The thought was the rings were bad allowing oil blow by. The hope was there was no damage to the cylinder walls and the crank would be undamaged. The good news is the overall condition of the block is good. No damage to the cylinder walls. The rods are in good shape. The rod bearings need to be replaced but that's literally $50. Cheap. The downside is the pistons. The ring landings where the rings sit were double the normal spec. So in essence the rings were flopping around as the pistons went up and down in the cylinders. The rings would not seal and thus oil blow by would continue. So I need another set of pistons! New pistons wouldn't be ideal because I'm not boring the cylinders. The old pistons are 89.47mm low compression piano tops. So about 8.3:1 compression. I was under the impression they were the 9.5:1 piano tops. That's the second thing about my engine that I was misinformed about. I thought it had a 284 cam in it but it was a plain old 264. So I found a used set of 89.47mm pistons at 9.5:1 that were in pretty good shape so that will give me a bit more power in addition to getting a more efficient.